vickers hardness test scale range|vickers hardness scale for metals : discounter A Vickers hardness tester should be calibrated to meet ASTM standard E10 specifications, acceptable for use over a loading range. Reference: ASTM E92-17, Standard Test Methods for Vickers Hardness and Knoop Hardness of . Lotaria Clássica - Jogos Santa Casa - Últimos Resultados - T.

{plog:ftitle_list}

WEBDo đó, để tải ứng dụng 789BET cho các thiết bị này, bạn cần thực hiện như sau: Bước 1: Mở ứng dụng Safari trên thiết bị của bạn để truy cập vào link chính thức của 789BET: 789betxv.com. Bước 2: Ngay phần tiện ích bên dưới .

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.The general principle of the Vickers and Knoop indentation hardness test consists of two steps: Step 1 - The applicable specified indenter is brought into contact with the test specimen in a .

A Vickers hardness tester should be calibrated to meet ASTM standard E10 specifications, acceptable for use over a loading range. Reference: ASTM E92-17, Standard Test Methods for Vickers Hardness and Knoop Hardness of .The Vickers hardness test at a glance: Ideal for micro hardness testing. Can be used for case hardness depth measurement, Jominy testing and hardness testing of welds. Standards: ASTM E384, ISO 6507 and JIS Z 2244. See our . Due to its scaling, the Vickers hardness test is ideal for testing hard materials like steel as well as softer materials like plastic. All in all, the Vickers test has one of the widest hardness ranges among the 4 test .Vickers hardness test is also known as the diamond pyramid hardness test which employs a diamond pyramid indenter and variable loads ranging from 1 to 120 kg. The Vickers hardness .

vickers hardness values explained

Vickers hardness testing is a preferred method for assessing the hardness of all types of metals, offering the most comprehensive range of hardness scale measurements .The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the .This document specifies the Vickers hardness test method for the three different ranges of test force for metallic materials including hardmetals and other cemented carbides (see Table 1).

EN ISO 6507-1 specifies he following are the three ranges of test force and their corresponding Vickers hardness test designations: F ≥ 49.03 N - Designation: HV 5 - Standard Vickers hardness test method for testing metals and materials with a medium to high hardness range. 1.961 ≤ F < 49.03 N - Designation: HV 0.2 to

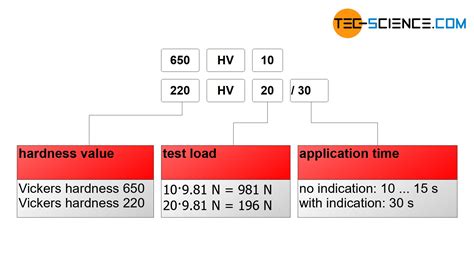

In the Vickers hardness test, a four-sided diamond pyramid is pressed into the material. The indentation surface serves as a measure of the hardness! . In special cases, the nano test range between 0.098 N (0.01 kp) and 1.961 N (0.2 kp) is also used (“nanohardness”). The pyramid tip used offers an additional advantage over the ball in the . Vickers: The Vickers test requires higher loads and longer indentation times compared to the Knoop test. Knoop: The Knoop test uses lower loads and shorter indentation times compared to the Vickers test. Material Suitability. Vickers: Vickers hardness testing is suitable for a wide range of materials, including metals, ceramics, and composites. The Vickers hardness measurement has a wide range, and it can measure materials with a hardness ranging from 10 to 1000 HV. The indentation is small in size. This measurement method is commonly used to measure thin materials and surface-hardened layers created through carburizing and nitriding.

Mohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material.. The scale was introduced in 1812 by the German geologist and mineralogist .The Knoop hardness test is similar to the Vickers test but uses a rhombic-based diamond indenter instead of a pyr- . and the Rockwell scale is a commonly accepted value when purchasing products. Applications for Rockwell Methods The Rockwell hardness test is widely used in various industrial . *Recommended hardness range according to EN ISO .

Total test force/N: Constant K: Hardness range: application examples: A: Diamond circular dimension: 100: 500: 600: 100: . The Rockwell hardness test is divided into various scales, each with a wide range of applications. . 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended.

The Vickers scale covers a broader hardness range compared to the Rockwell scale, making it a better choice when dealing with both very soft and very hard materials. Microhardness Testing: When you need to assess the hardness of thin films, coatings, or small-scale components, the Vickers test excels. Vickers hardness is determined by pressing a diamond square cone with a 136° top angle and a load of up to 120kg into the material’s surface. . Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based .Vickers Hardness Testing . The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. . range from 3 kgf (used in the “Superficial” Rockwell scale) to 10 kgf (used in .

The relationship between the two scales depends on the material and its hardness range. Here’s a simplified process for converting Vickers hardness (HV) to Rockwell hardness (HR): 1. Obtain the Vickers Hardness Value (HV): Conduct a Vickers hardness test on the material using the appropriate indenter and load for your material. 2.Vickers Hardness Testing Formulas, Calculator and Review . The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the .Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three hardness testing load ranges: in the micro, low-load and conventional (macro) hardness range.The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the . A square base pyramid shaped diamond is used for testing in the Vickers scale. For .

Devised in the 1920s by engineers at Vickers, Ltd., in the United Kingdom, the diamond pyramid hardness test, as it also became known, permitted the establishment of a continuous scale of comparable numbers that accurately reflected the wide range of hardnesses found in steels.The most common scale for this qualitative test is Mohs scale, . The various indenter types combined with a range of test loads form a matrix of Rockwell hardness scales that are applicable to a wide variety of materials. . The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an .The Vickers hardness test measures the maximum load applied to an object without its deformation exceeding a specified value. To measure the hardness, a diamond indenter is pressed against a test sample, and a specified load is applied. The indent’s measurement is then used to calculate the value of Vickers hardness which is translated and . The wide range of scales used within the Rockwell method (30 in total!) makes it suitable for many applications. However, despite its versatility, it does lack practicality when measuring smaller objects, for which other types of hardness testers are needed. . An alternative to Vickers, the Knoop hardness test is a microhardness test used .

1.1 Vickers Hardness. The Vickers test employs a square-based pyramid with an angle of 136° between opposing faces. The Vickers hardness is defined as the applied load P divided by the surface area of the impression. . In Al/Mg joints, the hardness values within the WNZ range from 54 to 220 HV [112, 114]. Khodir and Shibayanagi noted a .The Vickers hardness is the quotient of the test load (F in kgf) for the area of the indent (in mm), considered to be an upside-down pyramid with a square base. VICKERS APPLICATION SCALES: The test forces in kgf define the Vickers hardness scales. Vickers scale Knoop scale Test force (N) Test force (kgf) Test force (g)

The HRA scale covers the broadest hardness range, but this scale is not commonly used. In the Vickers test, the load is applied smoothly, without impact, and held in place for 10 or 15 seconds. . Fig. 5 - Load vs. Vickers hardness test results for two testers using a quenched and tempered 440C martensitic stainless steel specimen. Tester A is .Hardness test methods. . There are several hardness scale conversion systems, including BS 860 and ASTM E140. The table shows a set of values that has been used for stainless steels and also includes a tensile strength, (UTS), comparison. The Rockwell B values are superimposed on this table using an approximation from ASTM E140 Table5, which .

vickers hardness testing machine diagram

Minimum of two test blocks with at least one test block for each scale to be verified. At least two of the test blocks shall be from different hardness ranges. The difference between two blocks shall be a minimum of 100 points. The highest test force shall be verified on a block from the lower hardness range to product the largest indentation size.5. Wide Hardness Range. The Vickers hardness test can measure a wide range of hardness values, from very soft materials to extremely hard ones. This makes it suitable for testing materials with a wide range of mechanical properties, including those used in aerospace, automotive, and construction industries. 6. Microhardness Testing

vickers hardness test chart

vickers hardness scale for metals

bottled water container colifrm testing

Resultado da Nebulb software release. ⭐ If you like landscape astrophotography and you want to get the most out of your photos: https://nebulb.com/ This is the video presentation .

vickers hardness test scale range|vickers hardness scale for metals